In Part 1 of this article, we have discussed some types of hand weaving looms including the simple loom, the tapestry loom, the kilim and carpet loom, as well as, the rigid heddle loom and the table loom. Next, we will explain the remaining types of looms.

1- Floor loom:

The floor loom is considered as the bigger version of the table loom but it uses treadles in order to move the shafts with 4 different methods. Floor looms could be categorized into 4 different types according to how the shafts are moved: jack loom, countermarch loom, counterbalance loom and dobby loom. All these types of looms have shafts, they just differ in how these shafts are moved as we will explain.

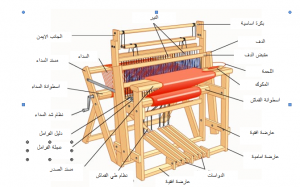

The Main Components of Floor Looms

- Warp beam

- Fabric beam

- Warp brakes and release System

- A reed hung up or fixed down to an axis

- A weaving shuttle either manual or fixed to the reed so as to push the weft into the shed

- Tie-up for tying treadles to shafts

- Shaft moving system

The following diagram shows the main components of looms:

a. Jack Loom

The movement of shafts in the jack loom depend on using treadles and a set of levers to raise or lower the shafts. In the loom illustrated below, upon pressing on a treadle, which is tied to a set of levers via the tieup according the wanted design, the set of shafts connected to this treadle is lowered forming the required shed which is bottom open in this case.

Jack Loom

Jack Loom -Bottom Open Shed

In the next illustration, treadles are connected to levers capable of raising shafts upon pressing on treadles, forming a top open shed. Shafts are joined to levers using chains.

Jack Loom – Top Open Shed

Advantages

- Theoretically infinite number of patterns that could be implemented according to the number of shafts

- Simple loom design

- Easy tie-up operation

- Easy to install and maintain

- Easy to add or remove a shaft

Disadvantages

- Because some warp threads are raised or lowered, they are highly stressed in comparison to the other threads, which has a negative impact on them.

- The back shafts ought to be raised farther or lowered farther in order to get a clear shed.

- Some patterns make certain shafts highly utilized which has a negative impact on warp threads.

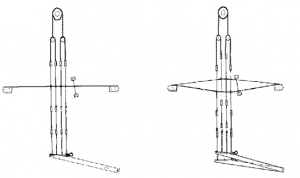

b. Counterbalance Loom

In this kind of loom, every pair of shafts is interconnected by means of a pulley; if one shaft is pulled down, the other one is raised up. As a result, the shed formed is regular and open in either direction up o down. Additionally, 4 shafts can be used where every pair is interconnected in the same way then pairs are interconnected as illustrated below:

The following image illustrates a type of counterbalance loom that uses the method we have just explained:

4-shaft Counterbalance Loom

Advantages:

- The formed shed is very clear.

- The force applied for pressing on the treadles is low

- Preferred to be used in weaving rugs

- The tie-up is very simple.

- Uniform tension upon all warp threads in every weaving process

Disadvantages:

- Quite limited to 4 shafts, as the more shafts, the harder to control.

- The shed is unclear if 1 shaft is used opposite to 3 shafts.

c. Countermarch Loom

In this kind of loom, each shaft is connected to a couple of levers, one that raises that shaft up and another that pushes it down. The treadles are tied in such a way that a set of shafts is connected to each one via the raising levers and lowering levers, depending on the required pattern. Consequently, upon pressing on a treadle, a set of shafts is raised up and another one is lowered down. This loom is used for weaving all types of textiles.

Countermarch Loom

Countermarch Loom

Advantages:

- The formed shed is very clear for any shafts arrangement.

- A big number of shafts can be used.

- The tension applied to the warp is the same all over the weaving process..

Disadvantages:

- Connections of lever systems are complicated.

- All shafts need to be joined to both lever systems and treadles.

- The more shafts, the heavier pressing on treadles.

d. Dobby Loom

Having a lot of shafts (12 shafts or more), the treadle load gets too high and the tie-up operation gets very difficult and complicated. As a result, a mechanical system is utilized; it enables the weaver to select the shaft that needs to be raised or lowered by pressing on a single treadle, It is considered as a simple mechanical program. The dobby loom is characterized by being capable of making unique patterns as well as having a single treadle that helps the weaver to a great extent. However, it needs training and high skill to use. The image below illustrates a dobby loom:

Dobby Loom

Dobby Loom

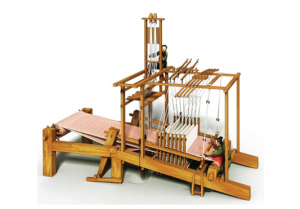

2- Draw loom – Jacquard loom:

From the above, it is clear that the more shafts the more possible it is to make manifold and unique patterns, but the number of shafts is limited to 64 in some looms. To have more control on the warp, a heddle is placed for every thread individually, but being tedious for the weaver he may need someone else to do this job with him i.e: 2 persons work on the loom, one pulls the required heddle and the other does the weaving job. This concept has developed that it could be possible to control each warp thread quite individually, which is adopted in the jacquard loom that has been able to create artistic drawings by weaving.

The following are illustrations for the the drawloom in the past and for the jacquard loom:

Drawloom

Jacquard Loom

Dr. Osama Abdel-Monem Abdel-Halim Shaaraf

مقال جيد وشرح متقن. جزاكم الله خيرًا.

شكرًا بارك الله فيكم.

السلام عليكم ممكن اعرف تكلفة سعر النواب كام يا فندم لو امكن

شكرا لك دكتور على التوضيح و وإذا كان بإستطاعتك شرح لنا كيف نحسب كل خيط على النير في كل نوع من القماش

ثانيا هل نستطيع تصنيع القماش الذي يصنع على النول اليدوي بالماكنات الصناعية

و في الأخير شكرا شكرا و بارك الله فيك

لوسمحتم كم سعر نول تبع شرايط هل تشحنوه لسعوديه

السلام عليكم

أهلا بك

يرجى التكرم من حضرتك بالتواصل معنا عن طريق الواتساب على رقم

00201282216930

شكرا لك

ياجماعة الخير

انا عايز نول لشخص مبتدئ لكن يكون عملي في الإنتاج وين أجد المعدات

السلام عليكم ورحمة الله وبركاته

اهلا بحضرتك

يمكنك التواصل مباشرة مع الدكتور اسامة شرف للاستفسار عن النول المناسب لغرضكم

00201282216930