Description

Introduction

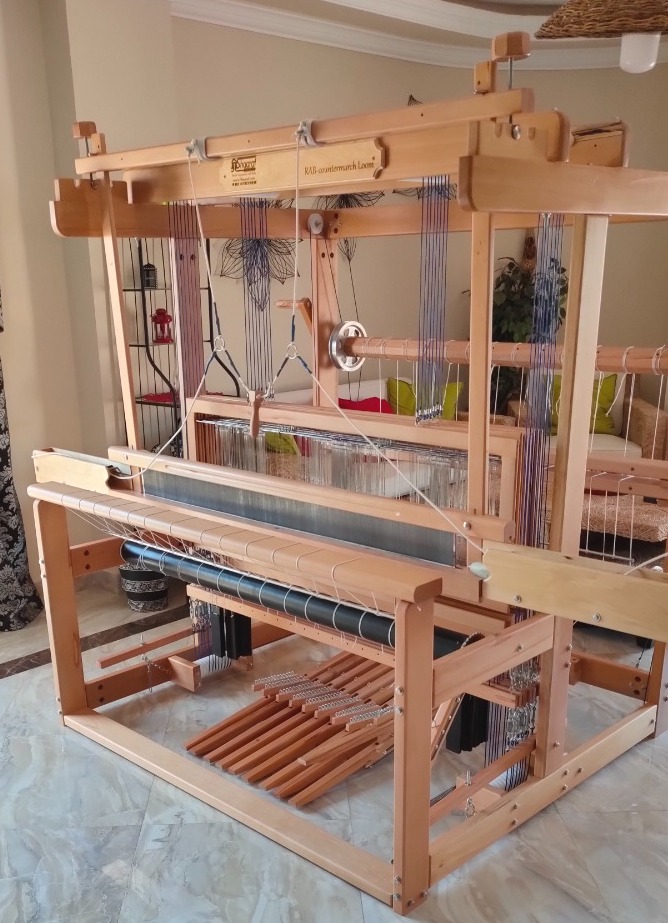

Countermarch looms are categorized under floor looms. In countermarch looms the treadles lift a set of shafts and lower the other one. They include 2 sets of lams not 1 as is the case for jack looms and counterbalance looms; this option sustains tension along all the warp threads during the weaving process. The shafts are positioned in a way that makes the warp on the same level as that through which the connecting line between the warp beam and the breast beam passes crossing the heddle eye; this maximizes the warping tension without affecting the shafts or vice versa when no weaving is performed. Besides, this enables using the countermarch loom for producing textiles with high-tension loaded warp.

Countermarch looms are considered the perfect choice for producing all kinds of textiles whether using normal threads or inelastic threads such as linen. They can produce fabrics that need uniform tension on their warp. In addition, they can make silk fabrics as their back shed length is highly extensible and they are perfect too for producing klim and tapestry.

Countermarch looms come with different potentials which allow them to be used for home or professional production according to their specifications.

Usages

There are various usages of countermarch looms, which can be summarized as follows:

Education and Training: Being perfect tools for weaving all textiles including klim and even using inelastic threads, countermarch looms can be used for educational purposes in colleges and institutes as well as workshops for training on either manual or mechanical weaving.

Professional production: Countermarch looms are reliable for getting textiles with compatible widths. In addition, they can be used with novelty yarns to have novelty fabrics.

Personal production: Countermarch looms are so easy that almost anybody can work on them (even children) to have great textile products for themselves or their loved ones.

Creating test fabric samples: Countermarch looms are useful for creating fabric samples before implementing them in mass production.

Mass production: Countermarch looms can be used for mass production considering the fact that treadles accelerate production rather than manual levers.

Rabab Countermarch Loom Features

Several selections that suit your needs: Shaaraf Textile Equipment and tools provide the Rabab Countermarch Loom with 3 different weaving widths: 80 cm, 100 cm and 120 cm. The number of shafts is either 4, 8 or 12 and the corresponding number of treadles is 6, 8 or 10 respectively.

Get diverse textiles: The shafts are positioned in a way that makes the warp on the same level as that through which the connecting line between the warp beam and the breast beam passes; this maximizes the warping tension without affecting the shafts or the threads when no weaving is performed. In addition, the lifting mechanism lifts some shafts and lowers the others according to the design and this option makes the loom optimal for weaving diverse textiles with diverse tensions, for ex: high-tension warping textiles like klim and tapestry, textiles using inelastic threads or even normal textiles.

Fabric consistency: You can set the rear warp beam’s height by lifting or lowering it so that the fabric construction wouldn’t impact the appearance and texture of the textile. That is how the countermarch loom can sustain the appearance and texture of both surfaces of the fabric.

High quality materials: Rabab countermarch looms are mainly made from dry Beech wood but dry oak wood could be used instead upon request. Stainless steel is used for making the axes, the ratchet’s gears and the ratchet itself. The stainless steel gears make high tension possible which enables the weaver to produce special fabrics.

A piece of art in your house: Rabab looms are durable for long-term use owing to being manufactured masterly with high quality materials. Plus, considering the aesthetics in designing the Rabab loom makes it a piece of art that adds a beautiful artistic touch to your house.

Excellent finishing: the wood is insulated with a layer of a special material and suitable lacquers.

Various attachments: Additional parts can be attached to the loom; you can check them out in the website’s store.

Rabab Countermarch Loom Highlights:

– Weaving width ranging from 80 cm to 250 cm (special widths up to 500 cm are available on order).

– 8, 4, or 12 shafts.

– Frictional brakes.

– Can be supplied with 2 warp beams.

– High productivity and ability to make various products: shawls, scarfs, tablecloths, bed sheets, kilim, upholstery, and many more.

– The structure is convenient for either homes (small-sized versions) or workshops (large-sized versions).

– A cloth advance system can be added, and a single or double shuttle box to weave with 2 colors .

– The structure is made from insulated beech wood and painted with Nitrocellulose lacquer.

– All the axles are made from stainless steel.

– The shafts’ bars are made from stainless steel.

– Metal cloth beam.

– Heddles can be easily added at any time.

– Reeds can be replaced at any time.

– Warranty is provided. Spare parts and maintenance are available.